The approved Plastics Directive introduces, among others, a ban on handling styrofoam boxes and cups to become effective as from 2021. This means that EPS packaging products need to be replaced with new materials meeting the requirements of the circular economy, which offers great opportunity for producers of modern packaging.

Big changes on the packaging market already in 2021

In 2019 the European Council and Parliament signed the directive (so called Plastics Directive), which reduces the impact of certain plastic products on the environment. According to this document, in Poland as from July 2021, it shall be forbidden to produce and sell 10 the most popular single-use products that have their biodegradable counterparts. These include food containers and cups made of EPS - expanded polystyrene formerly known as styrofoam. Resulting from this change in law, many companies (in particular fast-food sellers) shall be interested in the new type of packaging similar to the withdrawn single-use ones made of EPS. Great development boost is ahead of those companies using expanded materials for production of reduced weight packaging while keeping the required properties.

The Plastics Directive gives a reason

The new law motivates the packaging industry to prepare new type of products for its customers. KGL is one of those plastic product manufacturers that responded to the market needs. The activities undertaken by the company are focused on designing expanded materials, while a number of R&D works concerning material structures and production tools are executed in the company’s Research and Development Centre. Purpose of this is to launch industrial production of innovative foil and packaging designed primarily for the food sector.

The R&D Centre has been recently preparing the below:

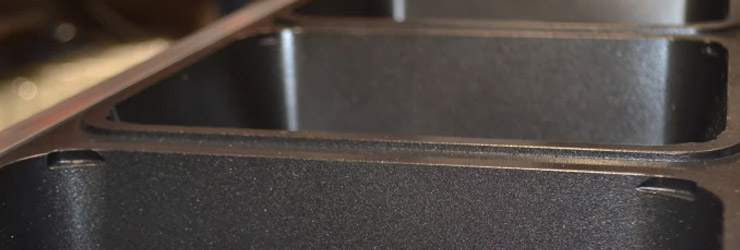

- Tools for expanded CPET packaging characterized by high thermal resistance up to 200°C and increased insulating power of the final products;

- Expanded CPET packaging (such as cups for hot drinks) of a structure that limits the material wastes and reduces weight of the final product (raw material savings while maintaining the quality parameters);

- Packaging for diary industry made of foamed PET produced in 100% of recycled materials.

Other issue that the Research & Development Centre is currently working on concerns preparation of production tools for expanded PLA packaging.